Germany TSDT1100 centrifuge differential transformation overhaul project delivered

Release time:

2021-07-30

Source:

An enterprise in Qinghai Province is currently using German TSDT 1100 settlement filter centrifuge. The differential on the centrifuge has been damaged in succession this year. Through the open bidding, our company received the notice of winning the bid on July 30, 2021, and signed the renovation and overhaul contract of 3 differential machines on September 2.

Due to the characteristics of the structure (different from other imported centrifuges in the industry), the output end of the differential is connected with the big end support of the hub through the bearing and connection bolt, and the output end of the differential is connected with the big end of the screw through the bearing and connection bolt, namely: The output end of the differential is supported on the big end support of the hub, at the same time, the output end of the differential is the big end support of the spiral! This structure, whether the precision of the hub or the precision of the helix, that is, the precision of the main engine, including any abnormal situation such as plugging material will directly act on the differential, for the normal operation of the differential greater influence! Moreover, in this form of structure, if you want to remove the differential, you must first disassemble the centrifuge rotor one piece at a time; Similarly, to reinstall the differential, you need to install the differential first, and then install the centrifuge rotor one by one.

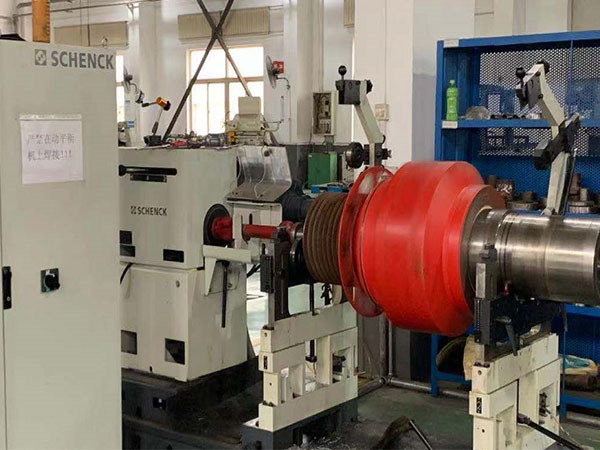

With the attitude of being responsible to customers and the spirit of being responsible for product quality, our company firstly made a number of design improvements to the differential and designed a special test stand to ensure the quality of the differential. Secondly, in order to ensure the whole rotor part to be used on the machine at one time, our company provided value-added services, such as free repair and dynamic balance detection of the main engine, to ensure the one-time success of the project.

At the same time, the customer was very anxious due to the damage of several pieces of equipment on the site. In order to meet the production demand of the customer, our company went all out since the contract was signed and worked overtime day and night. During the October holiday, our company also made overnight commissioning and test to ensure the delivery of one set of rotors (including differential) on October 3, 2021.

The remaining 2 rotors will be delivered on October 15, 2021.

Differential housing dynamic balance

Rotating hub dynamic balance

Spiral dynamic balance

Differential test run

Related News

Out with the spring, in with the summer, May should have been vibrant and thriving, but from time to time you can see a hint of sorrow and helplessness on the faces of Tianjin people. There is another outbreak of COVID-19. The city's affiliated districts and subdistricts are subject to control and quarantine, and people's lives and work are affected as a result.

As a type of core process equipment of large squeezing granulator units, a centrifugal dryer is used for the separation of water from resin granules and the drying after granulation. At present, the petrochemical industry has no large centrifugal dryer application ever.

Sparing No Effort to Achieve Our Mission

In order to ensure the successful completion of the business objectives and various tasks in 2022, Tianjin Promising Machinery Manufacture Co., Ltd. held the "Signing Ceremony of Letter of Responsibilities for Annual Objectives of 2022" on February 11, 2022.

Successful Conclusion of the Year-end Work Summary of 2021

With the joint efforts of all the staff of Promising, all the departments have accomplished the given objectives brilliantly and all of them have improved.

To the rose, the hand has lingering fragrance; Give love, harvest hope

On September 8, 2021, one of our employees suffered a severe illness and one of their family members was seriously ill and needed surgery. The sudden illness brought practical difficulties to the two employees and their family. Under the care and initiative of the leaders of the company, the General Office launched a charity activity for Master Wang and Master An in the workshop on September 9th. All the employees responded positively and raised the charity money within a few hours. Charity money is valuable, and love is priceless.

The characteristics of the material to be separated in the project are: flammable and explosive, small density difference, fine particle size, so the mixed liquid belongs to the material difficult to separate.