Significance of Centrifuge Repair and Maintenance Services

Keywords:

Category:

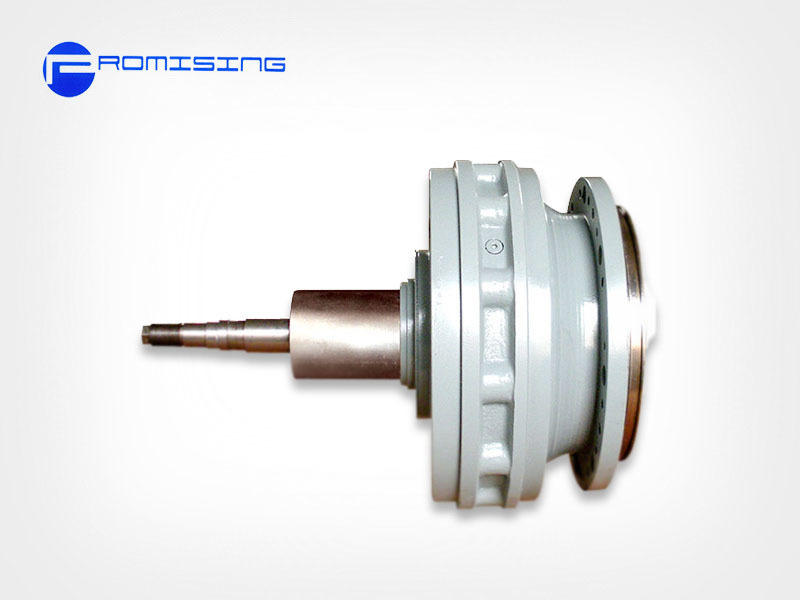

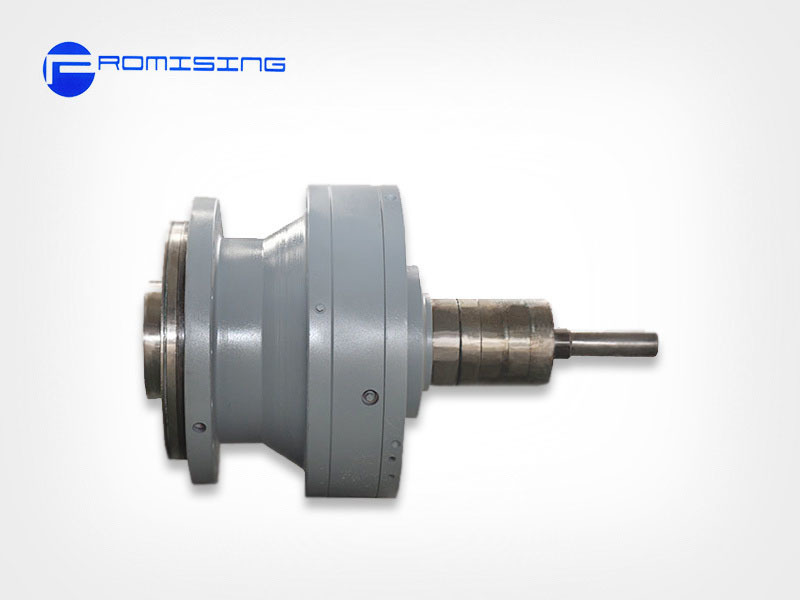

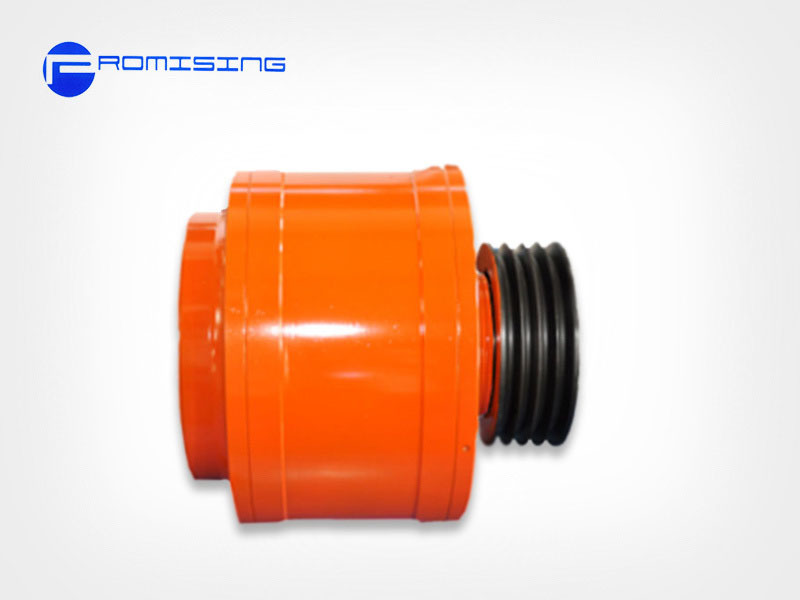

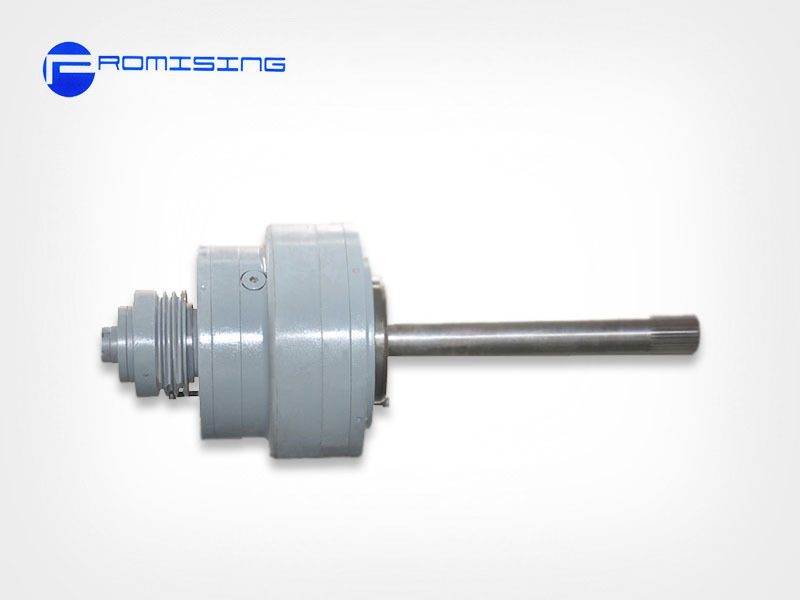

Maintenance about centrifuge、gear box and other precision equipment

Hotline:

Significance of Centrifuge Repair and Maintenance Services

A centrifuge is the key rotating equipment in the drying section of the PVC production process, and its stable operation plays a crucial role in the safe operation of the entire plant and production assurance.

However, the equipment is not a perpetual motion machine. After running for a period of time, it will suffer abrasion, deformation, aging, and other problems, so the regular maintenance of equipment is vital.

Centrifuge abnormalities are mainly manifested as abnormal vibration, temperature increase, or abnormal sound from the main bearing of the centrifuge. Once these problems occur, it shall be subject to shutdown immediately for timely servicing.

Standard procedures for repair and maintenance of centrifuges and differentials

1. Disassembly and cleaning

2. Accuracy inspection

3. Submission of a pre-inspection report

4. Development of a restoration process plan

5. Parts restoration

6. Dynamic balancing detection

7. Assembly and commissioning

8. Idling test

Through the above inspection and restoration, the equipment will reach the delivery inspection standard, with the safety hazards in the process of use solved, and a reliable guarantee for the next cycle of equipment operation is provided.

Previous

Next

Previous

Dynamic balancing

Next

Business Consulting

Related Products