Successful Delivery of Renovation and Overhaul Project of Differential for Siebtechnik TSDT1100 Centrifuge

An enterprise in Qinghai, which is currently using Siebtechnik TSDT 1100 screen-bowl centrifuges, has suffered damage to centrifuge differentials one after another this year. Through public bidding, we received the notification of award on July 30, 2021, and signed a contract for the renovation and overhaul of three differentials on September 2.

Keywords:

Category:

Hotline:

Successful Delivery of Renovation and Overhaul Project of Differential for Siebtechnik TSDT1100 Centrifuge

An enterprise in Qinghai, which is currently using Siebtechnik TSDT 1100 screen-bowl centrifuges, has suffered damage to centrifuge differentials one after another this year. Through public bidding, we received the notification of award on July 30, 2021, and signed a contract for the renovation and overhaul of three differentials on September 2.

Due to structural features (unlike other imported centrifuges of other brands in the industry), the output end of the differential of the Siebtechnik TSDT 1100 centrifuge is connected to the big end support of the drum by means of bearings and connecting bolts. At the same time, the output end of the differential is connected to the big end of the spiral through bearings and connecting bolts, i.e. the output end of the differential is supported on the big end support of the drum. In addition, the output end of the differential is equivalent to the big end support of the spiral! In this structure, either the accuracy of the drum or the accuracy of the spiral (i.e. the accuracy of the main machine), including any abnormalities such as blockage, will act directly on the differential, which has a greater impact on the normal operation of the differential! Moreover, for this structure, if it is required to remove the differential, the spiral conveyor of the centrifuge shall be disassembled one by one. Similarly, when reinstalling the differential, the differential must be installed first, and then the spiral conveyor of the centrifuge should be assembled one by one.

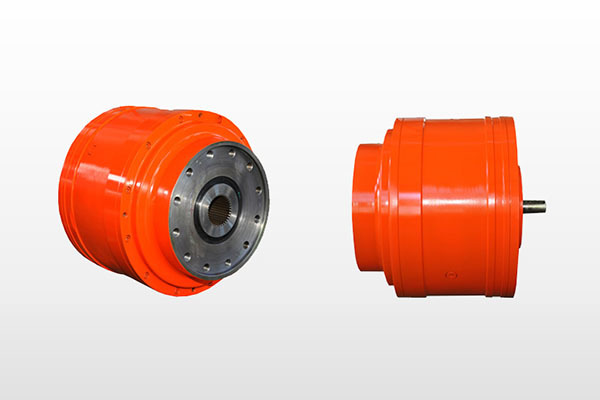

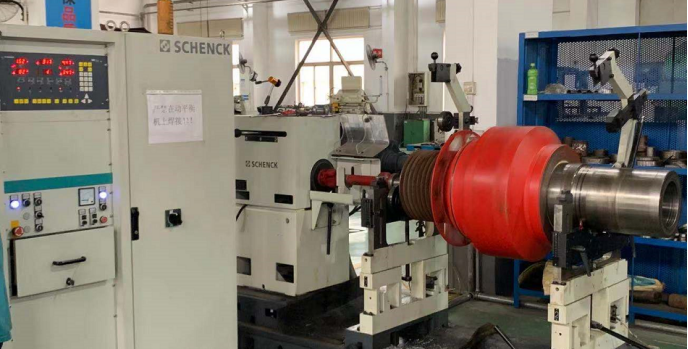

We arranged the following matters in the spirit of being responsible for customers and product quality. Firstly, our company made a number of design improvements to the differential and designed a special test bed to ensure the quality of the differential. Secondly, in order to ensure that the whole set of the spiral conveyor is effectively used on the machine at one time, we provided value-added services and carried out certain repair and dynamic balance testing on the main machine for free to ensure the one-time success of the project.

The customer was very anxious because several pieces of on-site equipment were damaged. In order to meet the customer's production demand, our company has been working overtime since the contract was signed. Even during the National Day Golden Week, our company also worked overnight for commissioning and test runs to ensure that one set of the spiral conveyor (including differentials) was delivered on October 3, 2021.

The remaining 2 sets of spiral conveyors will be delivered on October 15, 2021.

Dynamic Balance of Differential Housing

Dynamic Balance of Drum

Dynamic Balance of Spiral

Test Run of Differential

Business Consulting

Related Products